John A. Roebling, Joseph Strauss, Othmar Ammann, Man-Chung Tang, and Michel Virlogeux: Bridges

You’re asking about five monumental figures in bridge engineering! Here’s a summary of their key contributions and a brief overview of their most famous bridges, highlighting what made each distinct:

1. John A. Roebling (1806–1869)

- Era & Nationality: German-born American (19th century).

- Primary Innovation: Revolutionized suspension bridge technology by pioneering the use of wire rope cables, which he also manufactured. He developed the technique of spinning these cables in place.

- Signature Style: Known for robust, pioneering suspension designs often integrating majestic masonry towers and sometimes multiple decks (for both road and rail).

- Key Bridges:

- Brooklyn Bridge (New York City, USA): His ultimate vision and masterpiece. Although completed by his son, Washington Roebling, after his death, it was his groundbreaking design for the longest suspension bridge of its time (1883), featuring steel wire cables and unique masonry towers.

- John A. Roebling Suspension Bridge (Cincinnati, Ohio, USA): Completed 1867. A vital prototype for the Brooklyn Bridge, it was the longest suspension bridge in the world at its completion and allowed him to test many of his grand-scale concepts.

- Niagara Falls Suspension Bridge (New York/Ontario, USA/Canada): Completed 1855. The world’s first successful railway suspension bridge proved the feasibility of carrying heavy train loads on suspension structures.

- Roebling’s Delaware Aqueduct (Pennsylvania/New York, USA): Completed 1848. The oldest surviving wire suspension bridge in America, designed initially to carry canal barges, showcases his early utilitarian application of wire rope.

2. Joseph Baermann Strauss (1870–1938)

- Era & Nationality: American (late 19th/early 20th century).

- Primary Innovation: Revolutionized the design and mass production of bascule (drawbridges), building over 400 worldwide. He is most famous as the chief engineer who brought the Golden Gate Bridge to fruition.

- Signature Style: Efficient and standardized bascule designs. For the Golden Gate, he was the tenacious project leader, though others refined the final pure suspension design on his team.

- Key Bridges:

- Golden Gate Bridge (San Francisco, California, USA): Completed 1937—his defining achievement. As chief engineer, he led the monumental effort to build the world’s longest suspension bridge at the time, overcoming immense challenges.

- Palace Bridge (Dvortsovy Most, St. Petersburg, Russia): Completed 1916. A prominent example of his bascule bridge designs applied internationally.

- Burnside Bridge (Portland, Oregon, USA): Completed 1926—a notable early example of his patented Strauss bascule bridge system in the US.

3. Othmar Hermann Ammann (1879–1965)

- Era & Nationality: Swiss-born American (20th century).

- Primary Innovation: Master of long-span suspension bridges, known for their elegant, unornamented designs that achieved unprecedented lengths. He believed a great bridge should be a “work of art to which Science lends its aid.”

- Signature Style: Minimalist, structurally expressive, and highly efficient designs emphasizing clear forms and economical use of materials.

- Key Bridges:

- Verrazzano-Narrows Bridge (New York City, USA): Completed 1964. His final masterpiece and, upon completion, the longest suspension bridge in the world.

- George Washington Bridge (New York City, USA): Completed 1931. His first major independent project was the world’s longest main span suspension bridge at its completion. Famously left its steel towers exposed.

- Bayonne Bridge (Bayonne, New Jersey, USA): Completed 1931. A steel arch bridge that was the world’s longest steel arch at its completion, showcasing his versatility beyond suspension designs.

- Bronx–Whitestone Bridge (New York City, USA): Completed 1939. A slender suspension bridge was later stiffened to enhance aerodynamic stability after lessons from Tacoma Narrows.

4. Man-Chung Tang (b. 1938)

- Era & Nationality: Chinese-American (late 20th/21st century).

- Primary Innovation: A world leader in segmental bridge construction and pre-stressed concrete applications for long-span bridges, particularly cable-stayed bridges. He has designed or been involved with over 100 major bridges.

- Signature Style: Efficient, economical, and often record-breaking designs that maximize the potential of pre-stressed concrete and innovative construction methods, with a strong focus on constructability.

- Key Bridges:

- San Francisco-Oakland Bay Bridge East Span Replacement (California, USA): Completed 2013. Instrumental in the design of this massive self-anchored suspension bridge, a complex modern marvel for seismic resilience.

- Caiyuanba Yangtze River Bridge (Chongqing, China): Completed 2007. At its completion, the world’s longest arch bridge for dual highway and rail traffic, showcasing his expertise in multi-modal designs.

- Alex Fraser Bridge (British Columbia, Canada): Completed 1986. One of the longest cable-stayed bridges in North America at its time, it was a significant early example of large-scale pre-stressed concrete cable-stayed technology.

5. Michel Virlogeux (b. 1946)

- Era & Nationality: French (late 20th/21st century).

- Primary Innovation: One of the world’s foremost experts in cable-stayed bridges and very long-span suspension bridges. He is known for pushing the boundaries of span length, structural efficiency, and aesthetic elegance.

- Signature Style: Innovative, slender, and often record-breaking designs characterized by analytical rigor, exceptional aerodynamics, and a commitment to integrating structural efficiency with architectural beauty.

- Key Bridges:

- Millau Viaduct (Millau, France): Completed 2004. Arguably his most famous work, the world’s tallest bridge by structural height, is renowned for its elegant, minimalist design and aerodynamic stability.

- Normandie Bridge (Pont de Normandie, Le Havre, France): Completed 1995. When opened, the longest cable-stayed bridge in the world, pushing the limits of the technology for long spans.

- Vasco da Gama Bridge (Lisbon, Portugal): Completed 1998. Europe’s longest bridge, where Virlogeux played a crucial role in the design of its long-span cable-stayed and viaduct sections.

- Stonecutters Bridge (Hong Kong, China): Completed 2009. A super-long cable-stayed bridge, where he served as a key design consultant, is notable for its innovative tower structure.

These five engineers represent distinct eras and specialties. Still, all share a common thread of pushing the boundaries of what is possible in bridge building, leaving behind structures that are both functional marvels and enduring symbols of human ingenuity.

John A. Roebling, Joseph Strauss, Othmar Ammann, Man-Chung Tang, and Michel Virlogeux: Bridges Math

When discussing the contributions of bridge engineering giants like John A. Roebling, Joseph Strauss, Othmar Ammann, Man-Chung Tang, and Michel Virlogeux, “Bridges Math” refers to the sophisticated application of mathematical principles, physics, and structural mechanics that underpinned their designs and enabled the construction of increasingly longer, stronger, and more elegant spans. Their work pushed the boundaries of static and dynamic analysis, material science, and construction methodologies.

Here’s a look at the “math” central to each of their contributions:

1. John A. Roebling: The Math of Wire Rope Suspension

- Core Principles: Statics, elasticity, catenary curves, stress analysis of materials (especially steel wire).

- Mathematical Challenges:

- Cable Geometry (Catenary Curve): Roebling’s genius lay in his understanding and application of the catenary equation (y=acosh(x/a)), which describes the curve a hanging chain or cable forms under its own weight. He perfected the calculation of precise sag and tension in massive wire cables, ensuring uniform load distribution.

- Tensile Strength of Wire Rope: His innovation was manufacturing and calculating the tensile strength of his custom-made, high-strength wrought iron (and later steel) wire rope. The math involved understanding the cumulative strength of thousands of individual wires bundled together.

- Stiffening Trusses: To counteract deflection and oscillation (problems observed in earlier, lighter suspension bridges like the Tacoma Narrows Bridge, though this was later), Roebling incorporated stiffening trusses into his designs (e.g., the Brooklyn Bridge). The math here involved flexural rigidity calculations to distribute live loads more evenly across the main cables.

- Wind and Live Loads: Calculating how large, distributed loads (traffic, wind) would affect the bridge’s components and translating that into the necessary strength of cables and stiffeners.

- Impact: His work provided the mathematical and practical blueprint for modern long-span suspension bridges, proving their reliability for heavy loads like trains.

2. Joseph Baermann Strauss: The Math of Movable Bridges and Super-Project Management

- Core Principles: Lever mechanics, kinetics, strength of materials, and hydraulic engineering.

- Mathematical Challenges:

- Bascule Bridge Kinetics: Strauss’s patents revolutionized the bascule bridge. The math involved precise calculations of counterweights needed to balance the massive bridge leaves, allowing them to open and close smoothly with minimal power. This required balancing moments of force and understanding the dynamics of rotating heavy structures.

- Trunnion Design: Calculating the stress on the trunnions (pivots) that support the bascule leaves, ensuring they could handle massive rotating loads.

- Golden Gate Bridge (Chief Engineer): While the detailed suspension bridge math was largely done by Charles A. Ellis and Leon Moisseiff (involving advanced deflection theory for long-span suspension bridges under wind and live loads), Strauss’s role involved:

- Economic Optimization: Calculating the cost-effectiveness of various designs and materials.

- Construction Logistics: Massive logistical and statistical calculations for materials, labor, and sequencing in an unprecedented project.

- Aerodynamics (Early Considerations): Though not as advanced as later, there were calculations to understand basic wind forces on the deck.

- Impact: He made movable bridges efficient and ubiquitous, and his leadership on the Golden Gate project was a masterclass in managing immense engineering and financial calculations for a record-breaking structure.

3. Othmar Hermann Ammann: The Math of Elegant Long-Span Suspension

- Core Principles: Advanced structural analysis, aerodynamics, fatigue analysis, elasticity theory.

- Mathematical Challenges:

- Minimizing Redundancy: Ammann sought elegance through minimalism. The math here involved optimizing the structural system to carry loads with the least amount of material, requiring precise calculations of stress paths and material behavior.

- Aerodynamic Stability: After the Tacoma Narrows Bridge collapse (1940), Ammann became a leading expert in aerodynamics for bridges. His math involved analyzing how wind forces could induce dangerous oscillations (flutter and vortex shedding) and designing stiffening elements (trusses, deeper decks) to prevent them. This involved fluid dynamics and dynamic structural analysis.

- Material Optimization: Calculating the optimal use of new, higher-strength steels and concrete to achieve unprecedented spans while maintaining a slender appearance.

- Temperature Effects: Calculating expansion and contraction due to temperature changes over mile-long spans and designing expansion joints accordingly.

- Impact: He defined the aesthetic and engineering of mid-20th-century long-span suspension bridges, making them both incredibly long and visually graceful, underpinned by rigorous aerodynamic and structural math.

4. Man-Chung Tang: The Math of Segmental and Cable-Stayed Concrete

- Core Principles: Pre-stressed concrete mechanics, finite element analysis (FEA), segmental construction sequence analysis, seismic design, long-term creep and shrinkage of concrete.

- Mathematical Challenges:

- Pre-stressed Concrete: Tang is a pioneer in the application of pre-stressed concrete to long spans. The math involves calculating the optimal amount and placement of steel tendons within concrete members to induce compressive stresses that counteract tensile stresses from loads, allowing concrete to span much further than conventionally reinforced concrete.

- Segmental Construction: This method involves building bridges in pre-cast or cast-in-place segments. The math is highly complex, involving dynamic analysis of the bridge’s structural behavior at every stage of construction (as new segments are added and stressed), ensuring stability and precise geometry.

- Cable-Stayed Bridge Optimization: For cable-stayed bridges, the math involves optimizing the angles and tension in hundreds of individual cables to distribute loads efficiently and economically across the deck and towers. This often requires advanced FEA software to model complex interactions.

- Seismic Design (China): Designing bridges in highly seismic zones (like much of China) requires advanced dynamic seismic analysis to predict how a bridge will respond to earthquake forces and to design for ductile behavior.

- Impact: Tang revolutionized the design and construction of long-span concrete bridges, particularly cable-stayed and segmental bridges, globally, making them more economical and feasible for challenging sites.

5. Michel Virlogeux: The Math of Extreme Long-Span Cable-Stayed and Composite Bridges

- Core Principles: Advanced structural dynamics, aerodynamics (especially for very long spans), non-linear analysis, composite materials behavior, fatigue analysis.

- Mathematical Challenges:

- Aerodynamics of Record Spans: Virlogeux pushes the absolute limits of span lengths. The math here is incredibly complex, involving cutting-edge computational fluid dynamics (CFD) and extensive wind tunnel testing to predict and mitigate wind-induced oscillations (flutter, vortex shedding) in structures like the Millau Viaduct and Normandie Bridge.

- Composite Materials: Designing with composite materials (e.g., steel-concrete composite decks) requires advanced mathematical models to predict their combined behavior under various loads and long-term effects.

- Non-Linear Analysis: For extreme spans, the structural behavior can become non-linear, meaning traditional linear equations are insufficient. Virlogeux’s work involves sophisticated non-linear analysis to predict behavior under extreme loads and deflections.

- Fatigue Life: Calculating the fatigue life of cables and other components under millions of stress cycles over a bridge’s lifespan.

- Impact: Virlogeux has been instrumental in pushing the boundaries of record-breaking long-span bridges, particularly cable-stayed, making them elegant, efficient, and capable of spanning immense distances, underpinned by cutting-edge mathematical and computational analysis.

In essence, the “math” behind these engineers’ bridges evolved from fundamental principles of statics and elasticity to complex dynamic, aerodynamic, and computational analyses, reflecting humanity’s increasing ability to understand and master the forces of nature to create monumental structures.

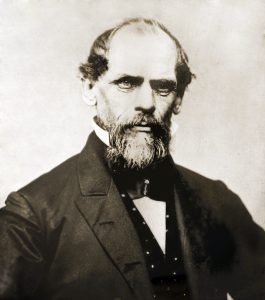

John A. Roebling (1806–1869)

Roebling, c. 1866

(Wiki Image By Unknown author – Online Collection of Brooklyn Museum; Photo: Brooklyn Museum, 2006, x882_PS1.jpg, Public Domain, https://commons.wikimedia.org/w/index.php?curid=10967039)

John A. Roebling Quotes

While John A. Roebling (1806–1869) was a meticulous engineer and visionary, he was not known for leaving behind a vast collection of philosophical or personal reflections in the form of direct quotes. His legacy is primarily etched in steel and stone, especially his groundbreaking suspension bridges.

However, his determination, confidence in his engineering, and the monumental nature of his most famous project, the Brooklyn Bridge, have led to some attributed statements and sentiments that reflect his character and vision:

- On the Brooklyn Bridge (vision and determination):

- “The great work is going on.”

- Context: This simple phrase, often attributed to him, encapsulates his unwavering focus and the immense scale of the Brooklyn Bridge project that consumed his life’s later years. It reflects the relentless progress of the construction.

- “No work could be more grand, more noble, or more deserving of all the skill and energy that man can bring to bear.”

- Context: This sentiment, often paraphrased from his writings or reports on the Brooklyn Bridge, illustrates his profound belief in the project’s significance and the dedication it demanded. He saw the bridge as a monument to human achievement.

- (Regarding the skepticism about building the Brooklyn Bridge) “All doubts, all cavils, all theories, must now give way to facts.”

- Context: This statement (or a strong paraphrase) reflects his scientific confidence in his engineering principles in the face of widespread doubts about the feasibility of such a massive undertaking. He believed the successful construction would speak for itself.

- “The great work is going on.”

- On the nature of his engineering work (especially wire rope):

- “I could construct bridges by an entirely new method, using wire cables… so strong that they would defy the forces of nature.”

- Context: This captures his pioneering spirit and absolute faith in his invention of wire rope for bridge construction, which was revolutionary at the time and proved far superior to traditional chain links for long-span suspension bridges.

- “The strength of the chain is in the weakest link; the strength of the cable is in the aggregate of its wires.”

- Context: This highlights his understanding of the inherent reliability of his wire rope cables, where the failure of a single wire does not compromise the entire cable, unlike a chain. This was a core principle of his design.

- “I could construct bridges by an entirely new method, using wire cables… so strong that they would defy the forces of nature.”

- On his work ethic and self-belief:

- “I have nothing to say but to stand by the plans and specifications.”

- Context: Reflects his methodical, precise, and uncompromising approach to engineering. He trusted his calculations and designs.

- “I have nothing to say but to stand by the plans and specifications.”

While these may not all be verbatim recordings of casual speech, they are widely associated with John A. Roebling through historical accounts and his surviving professional writings, capturing the essence of the visionary engineer who built the foundations of modern suspension bridges.

John A. Roebling YouTube Video

-

- One of the most epic engineering feats in history – Alex Gendler by TED-Ed: 1,499,571 views (http://www.youtube.com/watch?v=dyckL6HuLRU)

- Oldest Bridge on the Ohio River, Roebling Suspension Bridge, Cincinnati, Ohio by History in Your Own Backyard: 38,192 views (http://www.youtube.com/watch?v=CA7htW1HcJg)

- Architecture & Design, pt.5 | John Augustus Roebling by How to Architect: 20,340 views (http://www.youtube.com/watch?v=pHm5YSMAj_I)

- John A. Roebling and the Brooklyn Bridge – Hidden Genius by Stuff of Genius – HowStuffWorks: 19,554 views (http://www.youtube.com/watch?v=yGYUkRf_RKs)

- Virtual Museum: The Life and Times of John A. Roebling by National Museum of Industrial History: 1,320 views (http://www.youtube.com/watch?v=Vnq7yrh5XNU)

John A. Roebling History

Brooklyn Bridge: View from Manhattan towards Brooklyn, 2009

(Wiki ImageBy Suiseiseki – Own work, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=7648443)

John Augustus Roebling (born Johann August Röbling, 1806–1869) was a German-born American civil engineer whose revolutionary work with wire rope cables and suspension bridge design fundamentally transformed bridge construction in the 19th century. He is best known as the visionary behind the Brooklyn Bridge.

Early Life and Education (1806-1831)

- German Roots: Born in Mühlhausen, Prussia (now Germany) on June 12, 1806, Roebling was the youngest of five children. His mother, Friederike Dorothea, was ambitious and pushed for his education.

- Academic Brilliance: He attended the Royal Polytechnic Institute (Berliner Bauakademie) in Berlin from 1824 to 1826, where he studied architecture, civil engineering, bridge construction, hydraulics, languages, and philosophy (even attending lectures by Georg Wilhelm Friedrich Hegel). He graduated with a degree in civil engineering.

- Prussian Government Work: After graduation, Roebling spent three years working for the Prussian government, primarily on road construction projects in Westphalia. It was during this period that he reportedly saw his first chain suspension bridge in Bamberg, Bavaria, sparking his interest in the form.

- Immigration to America: The social and political unrest in Europe, coupled with his liberal political views and a desire to escape Prussian repression, led Roebling and his older brother Carl to immigrate to the United States in 1831.

Transition to Engineering and Wire Rope Innovation (1831-1848)

- Utopian Experiment: Initially, the Roebling brothers and other German emigrants bought land in Butler County, Pennsylvania, aiming to establish a utopian farming community called Saxonburg. However, John quickly realized farming was not his calling.

- Return to Engineering: In 1837, Roebling became a U.S. citizen and, after his brother Carl’s untimely death, sought employment as a surveyor and engineer for the state of Pennsylvania. He worked on canal systems and railroad routes, including the Allegheny Portage Railroad.

- The Wire Rope Invention (1841): It was while observing the Allegheny Portage Railroad, where heavy hemp ropes were used to haul canal boats over inclines, that Roebling noticed their frequent failures. In 1841, he invented a superior solution: wire rope made of twisted iron wire. This metal rope was significantly stronger, more durable, and safer than hemp.

- Founding a Business: The demand for his wire rope quickly grew. In 1842, he received his first U.S. Patent for his “Method of and Machine for Manufacturing Wire Ropes.” In 1848, he moved his wire rope works to Trenton, New Jersey, establishing the John A. Roebling’s Sons Company, which would become a world leader in wire rope manufacturing.

Pioneering Suspension Bridges (1844-1869)

With his wire rope successful, Roebling turned his full attention to bridge construction, applying his invention to suspension bridge design:

- Allegheny Aqueduct (1844-1845): His first structure using his wire rope, an aqueduct that carried the Pennsylvania Canal over the Allegheny River near Pittsburgh.

- Smithfield Street Bridge (Pittsburgh, 1846): His first major wire-cable suspension bridge for vehicular traffic, demonstrating his technology’s viability.

- Niagara Falls Suspension Bridge (1855): A groundbreaking achievement as the world’s first railway suspension bridge. This double-deck structure proved that suspension bridges could safely carry heavy train loads, a concept previously doubted.

- John A. Roebling Suspension Bridge (Cincinnati, 1867): Originally the Covington-Cincinnati Bridge over the Ohio River, this was the longest suspension bridge in the world at its completion. It served as a crucial prototype for the Brooklyn Bridge, allowing Roebling to test and refine many of his design and construction techniques on a grand scale. His eldest son, Washington A. Roebling joined him in his work in 1858.

The Brooklyn Bridge and Tragic Death (1869)

- The Grand Vision: In 1867, Roebling was appointed chief engineer for the ambitious project to span the East River, connecting Manhattan and Brooklyn. He designed a monumental suspension bridge with massive Gothic-inspired stone towers and four steel wire-rope cables.

- Fatal Accident: In July 1869, while surveying the site for the Brooklyn tower, Roebling’s foot was crushed between a ferry and a dock. Though initially treated, he opted for unconventional hydrotherapy, refusing traditional medical care. He contracted tetanus and died on July 22, 1869, at the age of 63, just as construction on his greatest masterpiece was about to begin.

Enduring Legacy

Despite his untimely death, John A. Roebling’s legacy is immense:

- The Brooklyn Bridge: His vision and meticulous plans were carried out by his son, Washington A. Roebling (who himself suffered crippling caisson disease), and Washington’s wife, Emily Warren Roebling. The bridge opened in 1883, standing as a testament to John A. Roebling’s engineering genius and foresight.

- Pioneer of Modern Suspension Bridges: He perfected the process and art of building wire-cable suspension bridges, adding new elements of strength, rigidity, and longevity. His cable-spinning method of stringing individual wires on-site has been used for virtually all large-scale suspension bridges ever since.

- Industrialist: The John A. Roebling’s Sons Company continued to thrive under his sons, producing wire rope for countless applications, including other famous bridges like the George Washington Bridge and the Golden Gate Bridge.

- Philosopher-Engineer: Roebling was a man of varied interests, including philosophy (influenced by Hegel) and social commentary. He believed in the moral application of science and technology, seeing bridges as symbols that could connect people and overcome divisions.

John A. Roebling was a true visionary whose innovations not only transformed bridge building but also contributed significantly to the industrial and infrastructural development of 19th-century America.

John A. Roebling: Top Five Bridges

Here are 5 of the top bridges associated with John A. Roebling (1806–1869), who revolutionized suspension bridge design:

- Brooklyn Bridge (New York City, USA)

- Completed: 1883 (completed by his son, Washington Roebling)

- Significance: Roebling’s ultimate vision and masterpiece. It was the longest suspension bridge in the world upon completion and the first to use steel wire for its cables. It’s an enduring icon of engineering and New York City.

- John A. Roebling Suspension Bridge (Cincinnati, Ohio, USA)

- Completed: 1867

- Significance: A vital prototype for the Brooklyn Bridge, this bridge over the Ohio River was the longest suspension bridge in the world upon its completion.

- Niagara Falls Suspension Bridge (Niagara Falls, New York/Ontario, Canada)

- Completed: 1855

- Significance: A groundbreaking achievement as the world’s first railway suspension bridge, demonstrating the feasibility of carrying heavy train loads on suspension structures.

- Roebling’s Delaware Aqueduct (Lackawaxen, Pennsylvania / Minisink Ford, New York, USA)

- Completed: 1848

- Significance: The oldest surviving wire suspension bridge in America, designed initially as an aqueduct to carry canal barges, showcasing his early mastery of wire rope for utilitarian purposes.

- Smithfield Street Bridge (Pittsburgh, Pennsylvania, USA)

- Completed: 1846 (original structure, later rebuilt but based on his principles)

- Significance: Roebling’s first major wire-cable suspension bridge proved the success of his technology for vehicular bridges and established his reputation.

John A. Roebling: Brooklyn Bridge

The Brooklyn Bridge, spanning the East River to connect Manhattan and Brooklyn in New York City, is the defining masterpiece and enduring legacy of John A. Roebling (1806–1869). Although he tragically died before construction truly began, his revolutionary design and meticulous planning laid the entire foundation for this iconic structure.

Roebling’s Vision and Groundbreaking Design:

- Longest Span in the World (at the time): Conceived in 1867, Roebling’s design for the Brooklyn Bridge was audacious for its time, calling for a main span of 1,595 feet (486 meters). Upon its completion in 1883, it was indeed the longest suspension bridge in the world, a title it held for seven years.

- Pioneering Steel Wire Cables: Roebling revolutionized suspension bridge construction by inventing and manufacturing wire rope cables. For the Brooklyn Bridge, he specified and used steel wire for the main cables – a first for such a large-scale project. He had also developed and patented the method of “spinning” these countless individual wires into massive, immensely strong cables directly on site, a technique still used today for large suspension bridges. The four main cables are each nearly 16 inches in diameter and contain over 5,000 galvanized steel wires.

- Hybrid Design for Rigidity: To ensure the bridge’s stability against wind and heavy loads (including future elevated trains), Roebling’s design incorporated a hybrid system that combined both the suspension cables and a rigid, stiffening truss system. He also included distinctive diagonal stay cables running from the towers to the deck, contributing to both its strength and unique aesthetic. He designed the truss system to be significantly stronger than he thought necessary (six to eight times), a wise decision that allowed it to survive despite some later discovery of inferior wire from a fraudulent supplier.

- Majestic Stone Towers: The two massive Neo-Gothic towers, rising 276.5 feet (84 meters) high, were built of limestone, granite, and cement. They were designed not only for their immense strength to support the cables but also for their architectural grandeur, serving as symbolic gateways between the two cities (Brooklyn and Manhattan were separate cities until 1898). These towers were higher than New York’s tallest office building at the time.

- Elevated Promenade: Roebling shrewdly included a broad, elevated pedestrian promenade above the roadways. He accurately predicted it: “In a crowded commercial city, it will be of incalculable value” – a testament to his foresight in urban planning.

Tragedy and Legacy:

- Fatal Accident: In July 1869, Roebling suffered a tragic accident while surveying the site for the Brooklyn tower. His foot was crushed between a ferry and a dock, leading to tetanus and his death just 24 days later, at the age of 63.

- Completion by the Roebling Family: Despite his death, John A. Roebling’s meticulous plans, calculations, and vision were faithfully carried forward. His eldest son, Washington A. Roebling took over as chief engineer. Washington himself suffered a debilitating case of decompression sickness (“the bends”) while working in the pneumatic caissons (underwater chambers used to build the tower foundations). Confined to his bed, he continued to direct operations, primarily with the vital assistance of his wife, Emily Warren Roebling, who became a highly competent engineer herself, relaying instructions and representing her husband on site.

- Enduring Icon: The Brooklyn Bridge opened on May 24, 1883, after 14 years of construction and $15 million. It was hailed as an “Eighth Wonder of the World,” a symbol of technological achievement, American ingenuity, and connecting people and progress. It remains an active and beloved landmark, showcasing the enduring power of John A. Roebling’s visionary design.

John A. Roebling: John A. Roebling Suspension Bridge

The John A. Roebling Suspension Bridge, connecting Cincinnati, Ohio, and Covington, Kentucky, is a pivotal masterpiece in the career of John A. Roebling (1806–1869). Completed in 1867, it served as a crucial prototype for the much larger and more famous Brooklyn Bridge, allowing Roebling to test and refine many of his innovative design and construction techniques on a grand scale.

Historical Context:

- Necessity for a Crossing: By the mid-19th century, Cincinnati was a booming industrial city, and the need for a permanent connection across the Ohio River to Covington, Kentucky, became increasingly apparent, especially to facilitate commerce and bypass unpredictable ferry services and winter ice.

- Roebling’s Vision: In 1855, the Covington and Cincinnati Bridge Company selected John A. Roebling as chief engineer. Roebling envisioned a suspension bridge that would not only be a functional crossing but also an engineering marvel and a symbol of progress.

- Challenges and Delays: Construction began in September 1856, but faced significant delays due to various challenges:

- The Panic of 1857, a nationwide economic downturn, caused funding to dry up, halting construction for several years.

- The American Civil War (1861-1865) further slowed progress, as materials and labor were diverted for the war effort.

- Opposition from steamboat and ferry operators, who feared the bridge would impede river traffic, also presented hurdles.

- Completion: Despite these setbacks, construction resumed in 1863, and the bridge officially opened to pedestrian traffic on December 1, 1866, and to vehicular traffic on January 1, 1867.

Architectural and Engineering Features:

- Record-Breaking Span: Upon its completion in 1867, the bridge’s main span of 1,057 feet (322 meters) made it the longest suspension bridge in the world, surpassing the Wheeling Suspension Bridge (1849). Roebling’s own Brooklyn Bridge later broke this record.

- Majestic Stone Towers: The two imposing towers, standing 200 feet tall, are constructed of sandstone and limestone, reflecting a Neo-Gothic architectural style. These towers provided the robust anchor points for the massive suspension cables.

- Pioneering Wire Rope Cables: The bridge utilized Roebling’s signature innovation: wire rope cables. The two main cables, each over 12 inches in diameter, were spun in place using Roebling’s unique process, consisting of thousands of individual wrought iron wires. A second set of steel cables was added during a significant reconstruction in the 1890s to accommodate heavier loads, effectively doubling the bridge’s strength.

- Diagonal Stays: A key feature of Roebling’s design was the use of diagonal stay cables (in addition to vertical suspenders) fanning out from the towers. These diagonal stays provided extra stiffness and load-carrying capacity, a technique Roebling would refine further in the Brooklyn Bridge. This hybrid “stayed suspension” system significantly improved the bridge’s rigidity and resistance to wind and traffic-induced vibrations.

- Durability and Longevity: Despite over a century and a half of service and numerous modifications to accommodate changing traffic loads (including the addition of a steel grid deck in the 1950s that gives it the “singing bridge” nickname), the bridge remains remarkably sound, a testament to Roebling’s foresight and robust engineering. It survived the devastating 1937 Ohio River flood, when it was the only passable bridge for 800 miles.

Significance and Legacy:

- Prototype for the Brooklyn Bridge: The John A. Roebling Suspension Bridge served as a crucial testing ground for many of the principles and construction techniques that Roebling would employ on the larger and more famous Brooklyn Bridge, including his cable-spinning method and the hybrid suspension-stayed system.

- Iconic Landmark: It quickly became an iconic symbol of the Cincinnati-Covington skyline, a beloved landmark, and a vital transportation artery.

- National Historic Landmark: The bridge was designated a National Historic Landmark in 1975 and a National Historic Civil Engineering Landmark by the ASCE in 1983. In 1983, it was officially renamed the John A. Roebling Suspension Bridge in honor of its visionary engineer.

The John A. Roebling Suspension Bridge stands as a powerful testament to Roebling’s genius, showcasing his innovative spirit and laying the groundwork for the future of long-span bridge engineering in the United States.

John A. Roebling: Niagara Falls Suspension Bridge

The Niagara Falls Suspension Bridge, designed by John A. Roebling (1806–1869), was a truly groundbreaking achievement in bridge engineering. Completed in 1855, it was unique for its time as the world’s first successful railway suspension bridge. It connected Niagara Falls, New York, with Niagara Falls, Ontario, spanning the formidable Niagara Gorge just below the famous falls.

Historical Context:

The mid-19th century saw a massive expansion of railway networks, and a bridge across the Niagara Gorge was essential to link American and Canadian lines (specifically the New York Central and Great Western Railway). However, many engineers of the era doubted that a suspension bridge could safely carry the heavy, dynamic loads of trains, fearing instability and collapse. Earlier attempts at railway suspension bridges had failed or proven impractical.

John A. Roebling, already a pioneer in wire rope manufacturing and suspension bridge design (having built the Monongahela Bridge and the Delaware Aqueduct), was commissioned in 1851 to undertake this challenging project. He adapted an existing temporary pedestrian bridge by Charles Ellet Jr. as scaffolding for his grander design.

Architectural and Engineering Features:

- Dual-Deck Design: Roebling’s innovative solution to the challenge of carrying railway traffic was a double-deck structure.

- The upper deck carried a single railway track (and later, a triple-gauge system to accommodate different railway gauges).

- The lower deck was for horse-drawn carriages and pedestrian traffic. This separation of traffic decks was a crucial design element, allowing for efficient use of the span and managing different types of loads.

- Wire Rope Cables: The bridge utilized Roebling’s signature innovation: four massive main cables, each 10 inches (25 cm) in diameter, composed of thousands of individual wrought iron wires spun in place. These cables provided the primary support for the bridge.

- Stiffening Truss System: To ensure stability under the heavy and moving loads of trains, Roebling incorporated a robust stiffening truss system made of wood (later reinforced and eventually replaced with iron and steel). This truss, running the full length of the deck, helped to distribute concentrated loads and resist wind-induced oscillations and deflections, a critical aspect that other engineers thought impossible for railway suspension bridges. The entire superstructure effectively formed a rigid, hollow girder.

- Masonry Towers: The main cables were anchored to four massive stone towers (two on each side of the gorge), providing strong and stable anchor points.

- Diagonal Stays: In addition to the vertical suspenders, Roebling used numerous diagonal stay cables that fanned out from the towers to the deck. These stays provided additional rigidity and load transfer, further enhancing the bridge’s stability against dynamic forces.

Significance and Legacy:

- Proving Railway Suspension: The Niagara Falls Suspension Bridge was a monumental triumph that unequivocally proved the feasibility of building suspension bridges strong enough to carry heavy railway traffic. On March 8, 1855, the first locomotive crossed the bridge, causing a deflection of only a few inches, silencing skeptics worldwide.

- Prototype for Brooklyn Bridge: This bridge served as a crucial proving ground for many of the concepts and techniques Roebling would later employ on his most famous work, the Brooklyn Bridge, including the wire cable manufacturing process and the hybrid stiffening system.

- Vital Link: It became a critical international transportation link, facilitating trade and travel between the United States and Canada.

- Enduring Influence: Although the original wooden structure was later replaced with steel (by Leffert L. Buck in the 1880s) and ultimately replaced by the steel arch Whirlpool Rapids Bridge in 1897 due to increasing train weights, Roebling’s original design was a revolutionary step forward in bridge engineering and solidified his reputation as the premier suspension bridge builder of his era. It demonstrated his foresight and ability to combine scientific theory with practical construction.

John A. Roebling: Roebling’s Delaware Aqueduct

Roebling’s Delaware Aqueduct, also known as the Roebling Bridge, is a truly unique and historically significant structure in the career of John A. Roebling (1806–1869). Completed in 1848, it holds the distinction of being the oldest existing wire suspension bridge in the United States. It is considered by many to be the oldest existing suspension bridge in the world that largely retains its original principal elements.

Historical Context and Unique Purpose:

- Part of the D&H Canal: The bridge was built as one of four suspension aqueducts for the Delaware and Hudson (D&H) Canal. This canal system was vital for transporting anthracite coal from the mines of northeastern Pennsylvania to markets on the Hudson River and eventually to New York City.

- Solving a Bottleneck: The D&H Canal’s route required it to cross the Delaware River. Initially, this was accomplished via a problematic rope ferry that created bottlenecks and resulted in collisions with timber rafts floating downstream. To alleviate this, the D&H Canal Company approved a plan in 1846 to “build the canal above the river.”

- Roebling’s Solution: John A. Roebling, who had already successfully built a wire suspension aqueduct across the Allegheny River in Pittsburgh (1845), proposed his wire suspension design. This allowed canal boats to literally float across the river, elevated above the timber rafts and ice floes below, significantly improving efficiency and safety.

Architectural and Engineering Features:

- Suspension Aqueduct Design: Unlike a typical bridge carrying roads or railways, the Delaware Aqueduct was a water-filled wooden flume (trunk) suspended by wire cables. This flume carried canal boats and their towpaths (for mules pulling the boats) across the river. It was an ingenious solution to the challenges of canal navigation over a natural waterway.

- Pioneering Wire Rope Cables: The aqueduct is a prime example of Roebling’s groundbreaking wire rope technology. It is supported by two main cables, each approximately 8.5 inches (21.5 cm) in diameter, composed of 2,150 individual wrought iron wires spun in place using Roebling’s specialized machinery. These cables, which are still largely original, attest to his exceptional material science and construction methods.

- Stone Piers: The cables are anchored to massive stone piers, which also support the wooden trunk. These piers were designed to break ice floes in the river, further showcasing practical engineering for the environment.

- Covered Cables: The cables are hidden from view from the deck by the wooden sides of the canal trunk, which adds to the structure’s distinct appearance as a “water bridge.”

- Robustness: The cables were designed to support stresses far beyond the actual load of the water-filled aqueduct, demonstrating Roebling’s characteristic over-engineering for safety and durability.

Significance and Legacy:

- Oldest Surviving Wire Suspension Bridge: Roebling’s Delaware Aqueduct holds the distinction of being the oldest existing wire suspension bridge in the United States and potentially the world, still retaining most of its original structural elements.

- Prototype for Future Works: While not as famous as the Brooklyn Bridge, the Delaware Aqueduct was a crucial stepping stone in Roebling’s development, allowing him to further test and refine his wire rope technology and suspension bridge principles on a significant scale. The cable anchorage system used here, for example, was later refined for the Brooklyn Bridge.

- Transformation into a Vehicular Bridge: After the D&H Canal closed in 1898, the aqueduct was drained, its wooden sides and towpaths were initially removed, and it was converted into a toll bridge for vehicular and pedestrian traffic.

- Preservation and Restoration: In 1980, the National Park Service purchased the aqueduct. Through meticulous restoration efforts in the 1980s and 1990s, based on Roebling’s original plans, the wooden canal walls and towpaths were reconstructed, restoring their original appearance as an aqueduct. Today, it is part of the Upper Delaware Scenic and Recreational River and functions as a pedestrian and one-lane vehicular bridge, allowing visitors to literally walk across history.

- National Historic Landmark: It was designated a National Historic Landmark in 1968 and a National Civil Engineering Landmark in 1972.

Roebling’s Delaware Aqueduct stands as a powerful testament to John A. Roebling’s early genius, showcasing his innovative spirit and the remarkable longevity of his pioneering wire suspension technology.

John A. Roebling: Smithfield Street Bridge

The Smithfield Street Bridge in Pittsburgh, Pennsylvania, holds a significant place in the early career of John A. Roebling (1806–1869). Completed in 1846, it was his first major wire-cable suspension bridge designed to carry a highway, marking a crucial step in his pioneering work that would later lead to the Brooklyn Bridge.

Historical Context:

The bridge spans the Monongahela River in Pittsburgh. The site had a history of bridges, with a wooden covered bridge existing there since 1818. However, this structure was tragically destroyed in the Great Fire of Pittsburgh in 1845. The need for a robust replacement was immediate, and John A. Roebling, who had recently invented and patented his wire rope, seized the opportunity. His bid for a wire suspension bridge was significantly lower than traditional options, which secured him the commission.

Architectural and Engineering Features (Roebling’s Original Bridge, 1846-1883):

It’s essential to distinguish between Roebling’s original bridge (1846-1883) and the current Smithfield Street Bridge (1883-present), which features a different design by Gustav Lindenthal. Roebling’s original bridge featured:

- First Highway Suspension Bridge with Wire Cables: This was the first major roadway suspension bridge in the United States to utilize Roebling’s innovative wire rope cables. It demonstrated the practicality and strength of his new material for vehicular traffic.

- Multi-Span Design: The bridge had eight spans and was built on the surviving masonry piers of the previous wooden bridge. This multi-span nature presented unique engineering challenges for a suspension bridge.

- Complex Stiffening System: To handle heavy moving loads and unbalanced loads across its multiple spans without excessive deflections, Roebling’s design incorporated a complex, indeterminate structural system. This included:

- Main suspension cables (two per span, suspended from cast-iron towers).

- Pendulum cable supports (suspenders).

- Stiffening trusses: Built into the railings and as underfloor bracing.

- Inclined stays: Diagonal cables intended to provide additional rigidity.

- This combination aimed to create a robust structure that could resist the dynamic forces of horse-drawn vehicles and, later, even horse-drawn streetcars.

- Cast-Iron Towers: The cables were supported by cast-iron towers, an economically and technologically feasible choice in Pittsburgh, the “iron city” of the time. These towers were designed with open sides to allow passage for pedestrians along the sidewalks.

- Performance: Despite the complexity of its design and the limited theoretical tools for analyzing such indeterminate structures in the mid-19th century, Roebling’s bridge was considered sound and performed successfully during its service life. It carried loads far heavier than originally anticipated by the time it was replaced.

Significance and Legacy:

- Pioneer for Roebling: The Smithfield Street Bridge was a crucial stepping stone in Roebling’s career. It allowed him to further test and refine his wire rope technology and his complex stiffening systems for highway bridges. The lessons learned here were invaluable and directly informed his designs for even grander projects like the Niagara Falls Suspension Bridge and, ultimately, the Brooklyn Bridge.

- Proof of Concept: It provided tangible proof of the effectiveness and durability of wire-cable suspension bridges for significant traffic loads, building confidence in this relatively new technology.

- Replacement by a New Landmark: By the late 19th century, with increasing traffic and heavier loads, Roebling’s bridge was deemed obsolete. It was dismantled and replaced by the current Smithfield Street Bridge (1883), designed by Gustav Lindenthal, which is itself a National Historic Landmark and a significant example of lenticular truss design. However, the legacy of Roebling’s pioneering work at this site remains a vital part of Pittsburgh’s and America’s bridge-building history.

Although Roebling’s original Smithfield Street Bridge no longer stands, its conceptual and engineering innovations were fundamental to his development as a master bridge builder and played a key role in the evolution of modern suspension bridges.

Joseph Baermann Strauss (1870–1938)

The Joseph Strauss Memorial in San Francisco

(Wiki Image By © Steven Pavlov / http://commons.wikimedia.org/wiki/User:Senapa, CC BY-SA 3.0, https://commons.wikimedia.org/w/index.php?curid=15934100)

Joseph Strauss Quotes

Joseph Baermann Strauss (1870–1938), chief engineer of the Golden Gate Bridge, was known for his relentless determination, pragmatic approach, and often blunt communication style. While he was a prolific writer of technical papers and reports, his most memorable “quotes” often came from his public statements and his driven pursuit of the Golden Gate project.

Here are some attributed quotes and sentiments that reflect Joseph Strauss’s character and his work:

- On his determination and vision for the Golden Gate Bridge:

- “It is my purpose to build a bridge which shall not only be the greatest bridge ever built, but one that will be an object of beauty, simple in its lines, and harmonious with its surroundings.”

- Context: This quote encapsulates his ambition for the Golden Gate Bridge to be a landmark of both engineering and aesthetic achievement. While others refined the final elegant suspension design on his team, this reflects his overarching vision for the project.

- “The bridge will be built.”

- Context: A simple, declarative statement often attributed to him, reflecting his unwavering resolve in the face of immense political, financial, and engineering opposition that plagued the Golden Gate project for years.

- “It will be a bridge of the future.”

- Context: Expressing his belief in the bridge’s forward-thinking design and its lasting impact.

- “It is my purpose to build a bridge which shall not only be the greatest bridge ever built, but one that will be an object of beauty, simple in its lines, and harmonious with its surroundings.”

- On overcoming challenges and the engineering process:

- “Every difficulty is a call to service. It is a challenge that must be met.”

- Context: This highlights his resilient and problem-solving mindset, crucial for tackling a project as complex and challenging as the Golden Gate Bridge.

- “The man who is too busy to study is the man who never gets ahead.”

- Context: This reflects his belief in continuous learning and adapting, which was essential for staying at the forefront of bridge engineering.

- “Every difficulty is a call to service. It is a challenge that must be met.”

- Reflecting on his career and contributions:

- “I have built over 400 bridges, but the Golden Gate will be my monument.”

- Context: This emphasizes the singular importance of the Golden Gate Bridge to his legacy, even though he was a highly prolific designer of bascule bridges.

- “My life has been dedicated to bridging obstacles, physical and mental.”

- Context: A broader reflection on his career, seeing himself as a problem-solver who overcame not just engineering challenges but also public skepticism and political hurdles.

- “I have built over 400 bridges, but the Golden Gate will be my monument.”

- A perhaps apocryphal, but often cited, practical observation:

- “If you have a problem, solve it. If you can’t solve it, get someone who can.”

- Context: While not directly confirmed as a verbatim quote from him, this sentiment aligns with his pragmatic and results-oriented leadership style.

- “If you have a problem, solve it. If you can’t solve it, get someone who can.”

These quotes, whether from his direct pronouncements or reflecting his well-documented character, paint a picture of Joseph Strauss as a driven, confident, and highly ambitious engineer who transformed vision into concrete reality, most notably with the Golden Gate Bridge.

Joseph Strauss YouTube Video

- Golden Gate Bridge | The CRAZY Engineering behind it by Sabin Civil Engineering: 18,514,847 views (http://www.youtube.com/watch?v=E6tp8DCAJ-0)

- Building the impossible: Golden Gate Bridge – Alex Gendler by TED-Ed: 850,174 views (http://www.youtube.com/watch?v=EPd2w5d_qAk)

- What Do You Know About the Golden Gate Bridge? by Smithsonian Channel: 594,174 views (http://www.youtube.com/watch?v=6HygbD44_j4)

- The Golden Gate Bridge for Kids: Famous Landmarks for Children – FreeSchool by Free School: 341,379 views (http://www.youtube.com/watch?v=WKphjf3VZhA)

- Golden Gate Bridge Open (1937) by British Pathé: 54,193 views (http://www.youtube.com/watch?v=t_sm0OHQKrg)

- 30 Workers Fell While Building the Golden Gate Bridge by Smithsonian Channel: 3,204,752 views (http://www.youtube.com/watch?v=3VdlDzQyusI)

- Golden Gate Bridge: The Structure that Defined an Era | FD Engineering by Free Documentary – Engineering: 451,416 views (http://www.youtube.com/watch?v=NkdL_f6IEU0)

Joseph Strauss History

View from the Presidio of San Francisco, 2017

(Wiki Image By © Frank Schulenburg, CC BY-SA 4.0, https://commons.wikimedia.org/w/index.php?curid=60353189)

Joseph Baermann Strauss (1870–1938) was an American structural engineer, widely recognized as the driving force behind the iconic Golden Gate Bridge. His career was marked by ambition, tenacity, and a significant contribution to the field of movable bridges.

Early Life and Education (1870–1892)

- Birth and Artistic Family: Joseph Strauss was born in Cincinnati, Ohio, on January 9, 1870. He came from an artistic family; his mother was a pianist, and his father, Raphael Strauss, was a painter and writer.

- University of Cincinnati: He graduated from the University of Cincinnati in 1892. While there, he showed a keen intellect and diverse talents, serving as both class poet and president. His interest in bridges was reportedly sparked during a college hospital stay, where his room overlooked the John A. Roebling Suspension Bridge in Cincinnati.

- Early Ambition: His senior thesis at university proposed an audacious concept for a railroad bridge spanning the Bering Strait between Alaska and Russia, showcasing his early inclination towards large-scale, visionary projects.

Early Career and Bascule Bridge Specialization (1892–1920s)

- Apprenticeship and Innovation: After graduating, Strauss worked as a draftsman for various firms, including the office of Ralph Modjeski, a prominent bridge engineer. It was during this period that he became interested in improving the design of bascule (drawbridges). He developed a key innovation: using cheaper concrete counterweights instead of expensive iron ones, a concept initially met with skepticism.

- Founding his Own Company: In 1904, due to his ideas being rejected by his superiors, Strauss left Modjeski’s firm and founded the Strauss Bascule Bridge Company in Chicago. Through this company, he revolutionized the design of bascule bridges, obtaining numerous patents for his systems, most famously the “Strauss Trunnion Bascule” design.

- Prolific Bascule Builder: Strauss’s company achieved incredible success, designing and building over 400 bascule bridges across the United States and internationally. This established him as a leading expert in movable bridge technology globally.

The Golden Gate Bridge (1917–1937)

The Golden Gate Bridge project became the culmination of Strauss’s career and his enduring legacy, consuming nearly two decades of his life.

- Initial Proposal (1917): Strauss first proposed a design for a bridge across the Golden Gate Strait in 1917. His initial concept was a more utilitarian, hybrid cantilever-suspension design, which was met with skepticism and considered aesthetically unappealing by many.

- Relentless Champion: The project faced immense opposition due to its staggering cost (estimated at $35 million in 1930s money), the treacherous natural conditions of the strait (strong currents, high winds, seismic activity), and legal challenges from ferry companies and environmental groups. Strauss tirelessly lobbied, campaigned, and fundraised for over a decade, his unwavering determination being crucial in securing political approval and financial backing.

- Chief Engineer (1929): In 1929, the Golden Gate Bridge and Highway District was formed, and Joseph Strauss was officially appointed Chief Engineer.

- Team Collaboration and Design Evolution: While Strauss was the driving force and overall leader, the final elegant, pure suspension bridge design was largely the work of others on his team:

- Charles Alton Ellis: The brilliant structural engineer who performed the fundamental mathematical calculations and detailed design of the suspension system. Strauss famously and unfairly dismissed him.

- Leon Moisseiff: A renowned consulting engineer who contributed to the overall suspension design.

- Irving Morrow: The consulting architect, responsible for the bridge’s iconic Art Deco styling, lighting, and the famous “International Orange” color.

- Construction and Safety Innovations (1933-1937): Construction began in 1933 during the Great Depression, providing much-needed jobs. Strauss implemented groundbreaking safety measures, notably requiring the use of hard hats and, famously, a safety net strung beneath the bridge deck. This net saved 19 lives, forming the core of the “Halfway-to-Hell Club.”

- Completion: The Golden Gate Bridge officially opened on May 27, 1937. It was the longest suspension bridge in the world at the time and immediately became a global icon.

Later Life and Legacy (1937–1938)

- Final Years and Death: Strauss’s health declined significantly after the completion of the bridge. He died just over a year after its opening, on May 16, 1938, at the age of 68, from coronary thrombosis.

- Complex Legacy: Strauss’s legacy is complex. He is undeniably the tenacious visionary who made the Golden Gate Bridge a reality, driving the project through immense hurdles. However, he has also faced criticism for taking disproportionate credit and for his harsh treatment of some key collaborators, particularly Charles Alton Ellis.

- Enduring Monument: Regardless of the controversies, the Golden Gate Bridge stands as his ultimate monument, a testament to his ambition, engineering skill, and perseverance, continuing to inspire awe and serve as one of the world’s most recognizable landmarks. His statue stands on the San Francisco side of the bridge.

Joseph Strauss: Top Five Bridges

Here are 5 of the top bridges associated with Joseph Baermann Strauss (1870–1938), a prominent American structural engineer. While he is most famous as the chief engineer of the iconic Golden Gate Bridge (a suspension bridge), his extensive career primarily focused on revolutionizing the design and construction of bascule (draw) bridges, of which he built over 400 worldwide.

- Golden Gate Bridge (San Francisco, California, USA)

- Completed: 1937

- Significance: This is by far his most famous and iconic work. As Chief Engineer, Strauss led the monumental project through immense political, financial, and engineering challenges to completion. It was the longest suspension bridge in the world at its completion and remains a global landmark. While he spearheaded it, the elegant, pure suspension design was primarily refined by Charles Alton Ellis and Leon Moisseiff.

- Palace Bridge (Dvortsovy Most – St. Petersburg, Russia)

- Completed: 1916

- Significance: A prominent example of his bascule (movable bridge) designs, this double-leaf Strauss bascule bridge over the Neva River near the Winter Palace showcases his success with movable bridge technology on an international scale.

- Burnside Bridge (Portland, Oregon, USA)

- Completed: 1926

- Significance: An important early example of his patented Strauss bascule bridge designs in the United States, demonstrating his expertise in movable bridge engineering for urban infrastructure.

- Lewis and Clark Bridge (Longview, Washington / Rainier, Oregon, USA)

- Completed: 1930

- Significance: While a cantilever bridge rather than a suspension or bascule, this structure over the Columbia River showcases Strauss’s work on larger fixed spans and his versatility as a structural engineer beyond his specialty.

- Cherry Street Strauss Trunnion Bascule Bridge (Toronto, Ontario, Canada)

- Completed: 1931

- Significance: This bridge illustrates the widespread adoption of his patented Strauss trunnion bascule system across North America, highlighting his influence in the field of movable bridges.

Joseph Strauss: Golden Gate Bridge

The Golden Gate Bridge is the defining achievement and enduring legacy of Joseph Baermann Strauss (1870–1938), serving as chief engineer for this monumental project. Completed in 1937, it stands as one of the world’s most recognizable and iconic structures.

Joseph Strauss’s Role: The Driving Force

While the Golden Gate Bridge is a testament to the collaborative efforts of many brilliant engineers and designers, Joseph Strauss was undeniably the chief engineer and the tireless, relentless force who made the “impossible” bridge a reality.

- Visionary and Promoter (1917-1929): Strauss first proposed a design for a bridge spanning the treacherous Golden Gate Strait in 1917. For over a decade, he almost single-handedly championed the project. He faced immense opposition due to the colossal cost, the strait’s formidable natural conditions (deep, turbulent water, strong winds, seismic activity), and powerful legal challenges from ferry companies and environmental groups. Strauss’s tenacious lobbying, fundraising efforts, and public relations campaigns were crucial in securing the necessary political approval and financial backing. He tirelessly convinced a skeptical public and reluctant politicians of the bridge’s feasibility and economic necessity.

- Chief Engineer Appointment (1929): In 1929, after years of advocacy, the Golden Gate Bridge and Highway District was formed, and Joseph Strauss was officially appointed Chief Engineer.

- Project Management and Leadership: Strauss oversaw the entire project from conception to completion. His role encompassed not just engineering design but also the vast undertaking of project management, coordinating numerous contractors, managing budgets, and dealing with the immense logistical challenges of building such a structure during the Great Depression.

Design Evolution and Key Team Contributions:

It’s crucial to acknowledge that while Strauss was the chief engineer, the final, elegant, pure suspension bridge design was largely the work of others on his team. Strauss’s initial design was a less aesthetically pleasing, hybrid cantilever-suspension bridge.

- Charles Alton Ellis: A brilliant structural engineer hired by Strauss. Ellis performed the foundational mathematical calculations and detailed structural design of the suspension system, including the complex computations for cable sizes, tower stresses, and wind forces. His work was meticulous and critical to the bridge’s final form. Unfortunately, Ellis was controversially and unfairly dismissed by Strauss in 1931 and received little public recognition for his contributions at the time. A plaque honoring him was installed on the bridge in 2012.

- Leon Moisseiff: A renowned consulting engineer, particularly famous for his “deflection theory” for flexible suspension bridges. Moisseiff served as a consulting engineer on the project and collaborated closely with Ellis on the wind and deflection analysis that shaped the final suspension design.

- Irving Morrow: The consulting architect, responsible for the bridge’s iconic aesthetic elements. He designed the distinctive Art Deco styling of the towers, railings, and streetlights. He also proposed the bridge’s famous color, “International Orange,” choosing it for its visibility in fog and its harmony with the natural surroundings.

Construction Challenges and Safety Innovations:

The Golden Gate Bridge was built under extraordinarily difficult conditions:

- Environmental Hazards: Workers faced high winds, dense fog, strong ocean currents, and the deep, turbulent waters of the Golden Gate Strait. Foundations for the towers required blasting rock deep underwater.

- Safety Measures: Strauss was a pioneer in worker safety. He introduced unprecedented safety regulations, including:

- Hard hats: The first major construction project to mandate the use of hard hats for all workers.

- Safety nets: A massive movable safety net was installed beneath the bridge deck, costing $130,000. This net famously saved the lives of 19 men who fell, earning them the nickname “The Halfway-to-Hell Club.” Despite these measures, 11 men tragically died during the construction.

Completion and Legacy:

The Golden Gate Bridge officially opened on May 27, 1937, to massive fanfare, including a week-long celebration. At its completion, it was the longest suspension bridge in the world.

Joseph Strauss died just over a year after the bridge’s opening, on May 16, 1938. The Golden Gate Bridge stands as his ultimate monument, a testament to his ambition, engineering skill, and sheer perseverance in the face of daunting challenges. It remains one of the world’s most famous and recognizable landmarks, embodying human ingenuity and a triumph over nature.

Joseph Strauss: Palace Bridge

The Palace Bridge (Dvortsovy Most) in St. Petersburg, Russia, is a significant and historically important movable bridge, and it is indeed a prime example of the innovative bascule (drawbridge) designs developed by Joseph Baermann Strauss (1870–1938).

Historical Context:

- Necessity for a Modern Crossing: St. Petersburg, built on numerous islands and intersected by the Neva River, had long relied on temporary pontoon bridges that had to be disassembled for shipping traffic. As the city grew, the need for permanent bridges, especially across the main Neva River, became critical. The Palace Bridge was intended to link the central Palace Square with Vasilyevsky Island.

- International Competition: The design and construction of bridges over the Neva were complex and highly competitive. The initial design of the Palace Bridge was by Andrei Pshenitsky, but Joseph Strauss’s company handled the mechanical system for its movable span.

- Construction Period: Construction of the Palace Bridge began in 1912 and was largely completed by 1916, amidst the turmoil of World War I (and the final years of the Russian Empire, then known as Petrograd). Its official opening was in December 1916.

Architectural and Engineering Features:

The Palace Bridge is a multi-span cast-iron and steel bridge, but its most distinctive feature is its massive and powerful movable span:

- Strauss Bascule System: The central, two-leaf bascule span is the bridge’s hallmark. It utilizes Strauss’s patented Trunnion Bascule system, which allows the two enormous bridge leaves to lift vertically and pivot on trunnions (fixed axles). This system is highly efficient and counterbalanced by large concrete weights hidden beneath the deck.

- Opening for Navigation: The bridge’s primary function is to open at night to allow tall ships to pass through the Neva River, particularly during the navigation season (typically from April to November). The sight of the two leaves lifting dramatically is a famous spectacle for tourists and a vital part of the city’s logistical operations.

- Architectural Style: While fundamentally a functional structure, the bridge also incorporates architectural elements befitting its location near the Winter Palace. It features decorative railings, streetlights, and a robust, classical aesthetic in its fixed spans.

- Bridge Structure: The bridge consists of five spans. The three central spans are fixed, while the two largest spans in the middle are movable bascule leaves. Massive granite piers support the fixed spans.

- Dimensions: The total length of the Palace Bridge is approximately 250 meters (820 feet), with the central movable span being 50 meters (164 feet) wide when open.

Significance and Legacy:

- Icon of St. Petersburg: The Palace Bridge is one of the most famous and recognizable symbols of St. Petersburg. Its nighttime opening is a major tourist attraction, embodying the city’s unique relationship with its waterways.

- Example of Strauss’s Global Influence: The Palace Bridge stands as a testament to Joseph Strauss’s international impact as a bridge engineer. It demonstrates the widespread adoption and effectiveness of his patented bascule designs, even in distant and politically complex environments.

- Enduring Function: Despite its age and the dramatic historical events it has witnessed (including the Russian Revolutions), the Palace Bridge remains a crucial part of St. Petersburg’s transportation infrastructure, effectively managing both road traffic and vital river navigation. It has undergone several renovations and modernizations over the decades to maintain its functionality.

The Palace Bridge is a prime example of Strauss’s engineering prowess in movable bridges, a legacy that often overshadowed his most famous project, the Golden Gate Bridge, in terms of sheer numbers of structures.

Joseph Strauss: Burnside Bridge

The Burnside Bridge in Portland, Oregon, is a significant and historically notable movable bridge, and its key lift mechanism was indeed designed by Joseph Baermann Strauss (1870–1938), the renowned American structural engineer.

Historical Context:

- Replacing an Older Bridge: The current Burnside Bridge, completed in 1926, replaced an earlier swing-span truss bridge from 1894 that could no longer handle the demands of increasing traffic on Portland’s Willamette River.

- Design Team: While the overall bridge design was initially conceived by Ira G. Hedrick and Robert E. Kremers, and later completed and supervised by Gustav Lindenthal, the crucial bascule lift mechanism (the movable central part of the bridge) was designed by Joseph Strauss’s Strauss Bascule Bridge Company.

Architectural and Engineering Features:

- Strauss-Type Double-Leaf Bascule: The Burnside Bridge features a double-leaf Strauss Trunnion Bascule draw span in its center. This patented system, developed by Joseph Strauss, uses large, hidden counterweights that rotate downward within the piers to lift the bridge’s two leaves smoothly and efficiently. This allows the bridge to open for river traffic on the Willamette River.

- It was one of the heaviest bascule bridges in the United States at the time of its construction, partly due to being the first large-scale bascule bridge with a concrete deck on its movable span.

- Architectural Integration: The bridge is notable for its aesthetic design, incorporating Italian Renaissance-style towers and decorative metal railings. This was a result of input from an architect, reflecting the influence of the “City Beautiful” movement, which aimed to incorporate architectural ornamentation into engineering designs.

- Composite Structure: The bridge consists of two steel deck truss side spans and the central double-leaf Strauss bascule draw span, with both concrete and steel plate girder approaches.

- Lifeline Route: Even today, the Burnside Bridge is designated as a crucial “lifeline route” for emergency transportation in Portland, particularly in the event of a major earthquake, and has undergone seismic retrofitting.

Significance and Legacy:

- Example of Strauss’s Bascule System: The Burnside Bridge stands as a prominent example of Joseph Strauss’s widespread and successful bascule bridge designs in the United States. His firm built hundreds of these movable bridges globally, and the Burnside Bridge exemplifies his innovative approach to designing efficient and reliable draw mechanisms.

- Key Portland Landmark: It is a vital and iconic crossing in downtown Portland, linking the city’s east and west sides, and is a historically significant structure.

- Reflection on 20th-Century Bridge Building: The Burnside Bridge exemplifies the early 20th-century trend of integrating engineering functionality with architectural aesthetics in major infrastructure projects.

The Burnside Bridge serves as a tangible testament to Joseph Strauss’s specialized expertise in movable bridge technology, even amidst the broader design efforts of other prominent engineers.

Joseph Strauss: Lewis and Clark Bridge

The Lewis and Clark Bridge (also known as the Longview Bridge or Longview-Rainier Bridge) is a significant crossing of the Columbia River, connecting Longview, Washington, and Rainier, Oregon. It was indeed designed by Joseph Baermann Strauss (1870–1938), the renowned American structural engineer best known for the Golden Gate Bridge.

Historical Context:

- Necessity for Economic Growth: The bridge was a crucial project to facilitate the growth of Longview, Washington, a planned industrial city founded in 1923, primarily serving the timber industry. A permanent bridge was essential for the transportation of goods and people across the Columbia River, which was a significant barrier.

- Construction Period: Construction began in 1928, and the bridge was completed and opened to traffic in 1930. It was a privately funded toll bridge until 1947.

- Strauss’s Role: Joseph Strauss served as the chief engineer for the Lewis and Clark Bridge. While his fame predominantly rests on his bascule bridge designs and the Golden Gate, this bridge stands out as one of his more significant fixed-span projects.

Architectural and Engineering Features:

- Cantilever Truss Design: Unlike Strauss’s more famous bascule (movable) bridges or the suspension type of the Golden Gate, the Lewis and Clark Bridge is a cantilever truss bridge. This design was chosen for its suitability for long spans over navigable waterways where high clearances are required, without needing the deep foundations or extensive cable anchorage systems of a suspension bridge.

- The main span is 1,200 feet (366 meters) long, and it was the longest cantilever truss span in North America when completed.

- Its total length, including approaches, is over 8,100 feet (2.5 kilometers).

- Vertical Lift Span (Later Addition): Although originally a fixed cantilever bridge, a vertical lift span was added in the middle of the main span during construction to increase the navigable clearance for ships on the Columbia River. This added a movable element to the design, reflecting Strauss’s expertise in such mechanisms.

- Materials: The bridge is primarily constructed of steel trusses, with concrete used for piers and approach spans. Its robust, industrial aesthetic reflects the functional demands of its time and location.

- Height and Clearance: The bridge has a maximum vertical clearance of 196 feet (60 meters) above high water, ensuring it accommodates the large ships traveling on the Columbia River.

Significance and Legacy:

- Economic Catalyst: The Lewis and Clark Bridge played a vital role in the economic development of Longview and the surrounding region, enabling the efficient transport of timber and other goods and connecting communities.

- Showcase of Versatility: It demonstrates Joseph Strauss’s versatility as a structural engineer beyond his dominant expertise in bascule bridges and his leadership role in iconic suspension bridges. It shows his capability in designing large-scale fixed-span structures.

- Precursor to Golden Gate: Built just seven years before the Golden Gate Bridge, the Lewis and Clark Bridge provided Strauss with further experience in managing large-scale, complex projects, even if its structural type was different. The experience gained here likely contributed to his organizational and problem-solving skills, which were applied to the Golden Gate project.

- Enduring Landmark: The Lewis and Clark Bridge remains a vital transportation link today, handling substantial traffic and serving as a testament to early 20th-century American bridge engineering.

The Lewis and Clark Bridge stands as an important, albeit less famous, chapter in Joseph Strauss’s career, showcasing his broad engineering capabilities and his role in connecting vital economic regions.

Joseph Strauss: Cherry Street Strauss Trunnion Bascule Bridge

The Cherry Street Strauss Trunnion Bascule Bridge in Toronto, Ontario, Canada, is a prime example of a movable bridge designed by Joseph Baermann Strauss (1870–1938), the prolific American structural engineer. Completed in 1931, it showcases his widely adopted and patented bascule (drawbridge) system.

Historical Context:

- Industrial and Port Connectivity: The bridge was built to facilitate traffic flow over the Keating Channel, a critical waterway for industrial and port operations in Toronto’s inner harbour. It needed to accommodate both land traffic (vehicles, streetcars, pedestrians) and marine traffic (freighters, barges).